Continuous quality development is focused on improving the high-speed cold heading. In particular, we have achieved customer satisfaction through the development of special coatings and patent applications.

CHARACTERISTICS

Tight Diameter control: Can be managed within half the international standard.

Excellent coating.

- - Improve tool life with uniform coating

- - Excellent adhesion to reduce dust and provide a comfortable working environment

- - Easy multistage cold forming with special coating (G-Co, J-Co, GM-Co etc.)

Post-treatment: Easy post-treatment and provide a clean surface after heading.

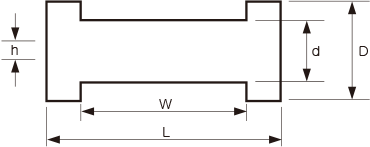

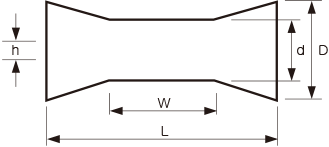

SPECIFICATIONS

ASTM, JIS, EN and other international standards and customized specifications to meet customer requirements

Grade : 304, 304L, 304CU, 316, 316L, 316CU, XM7(302HQ), 410, 430, 420J2 etc.

Production range : 0.80 ~ 20 mm

Surface : BR, DU (*BR : Bright surface with no lubricant)

Packing : Provide various packing type to meet required unit weight. (Spool, Carrier, Coil)

Surface : Provide various kinds of coating such as XC, CU, CM, JC, GC etc.