KOS provides high quality powder produced through EIGA(Electrode Induction Melting Inert Gas Atomization) system.

Characteristics

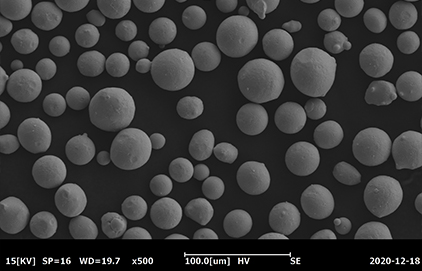

We provide high-purity spheronized powder

We manage the ideal distribution of grain size.

We can produce reactive metal (Ti, Zr) powder.

Product specifications

PBF (Powder Bed Fusion) : 10~53㎛

PBF-EBM (Powder bed fusion - Electron beam) : 45~150㎛

DED (Directed energy deposition) : 45~150㎛

Etc. (Customized powder size for other Additive manufacturing process)

Quality Control

Chemical composition

Particle size distribution by sieving (ASTM B214)

Particle size distribution by laser diffraction (ASTM B822)

Apparent / Tap density (ASTM B212 / ASTM B527)

Flowability (ASTM B213 and ASTM B964)

Powder Imaging (SEM)

Powder Cross-Section/Porosity Imaging (OM or SEM)

Application : ADDITIVE MANUFACTURING(AM), METAL INJECTION MOLDING(MIM), THERMAL SPRAY(TSA)

Ti Gr.2

COMPOSI

TION GRADE |

C |

O |

N |

H |

Fe |

| TI-2 |

Max 0.08 |

Max 0.25 |

Max 0.03 |

Max 0.015 |

Max 0.30 |

Specifications : ATSM B348, ASTM F67

Ti Gr.5

COMPOSI

TION GRADE |

C |

O |

N |

H |

Fe |

AI |

V |

Y |

| TI-5 |

Max 0.08 |

Max 0.20 |

Max 0.05 |

Max 0.015 |

Max 0.30 |

5.5 - 6.75 |

3.5 - 4.5 |

Max. 0.005 |

Specifications : ASTM B348, ASTM F2924

Ti Gr.23

COMPOSI

TION GRADE |

C |

O |

N |

H |

Fe |

AI |

V |

Y |

| TI-23 |

Max 0.08 |

Max 0.13 |

Max 0.05 |

Max 0.012 |

Max 0.25 |

5.5 - 6.5 |

3.5 - 4.5 |

Max. 0.005 |

Specifications : ASTM B348, ASTM F3001

Size

0~15㎛, 15~45㎛, 15~53㎛, 45~106㎛, 45~150㎛, Etc. (Customized powder size for other Additive Manufacturing process)

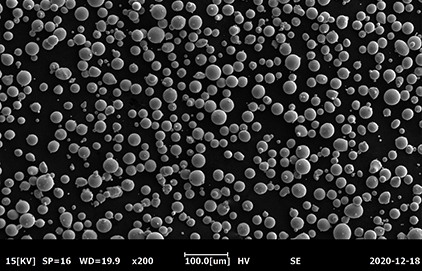

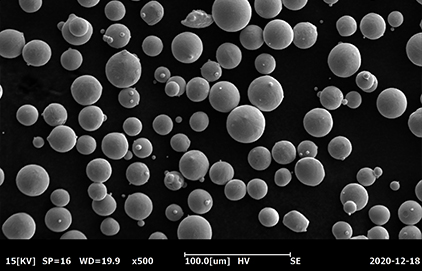

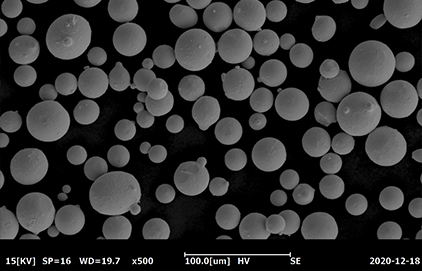

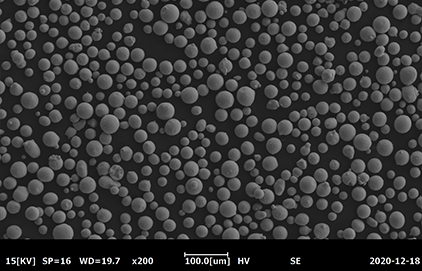

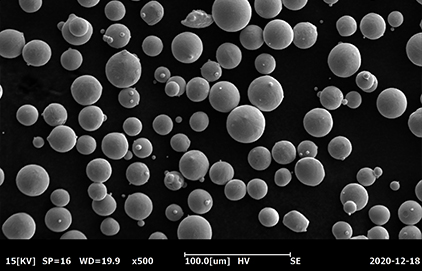

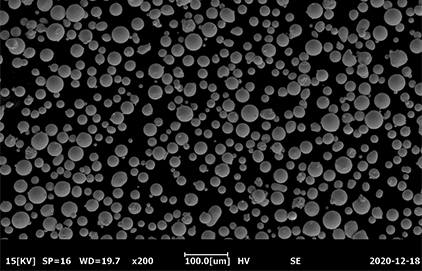

SEM image (Ti Gr.23 15~45㎛)

x200

x500

Application : Aerospace, Medical Devices

Package : 2.5KGS

ALY718 (IN718)

COMPOSI

TION GRADE |

C |

Mn |

Si |

P |

S |

Cr |

Co |

Mo |

Nb+Ta |

Ti |

Al |

B |

Fe |

Cu |

Ni |

| ALY718 |

Max 0.08 |

Max 0.35 |

Max 0.35 |

Max 0.015 |

Max 0.015 |

17.0 - 21.0 |

Max 1.0 |

2.80 - 3.30 |

4.75 - 5.50 |

0.65 - 1.15 |

0.20 - 0.80 |

Max 0.006 |

Re - mainder |

Max 0.30 |

50.0 - 55.0 |

Specifications : ASTM B637, ASTM F3055

ALY625 (IN625)

COMPOSI

TION GRADE |

C |

Mn |

Si |

P |

S |

Cr |

Co |

Mo |

Nb |

Ti |

Al |

Fe |

Ni |

| ALY625 |

Max 0.10 |

Max 0.50 |

Max 0.50 |

Max 0.015 |

Max 0.015 |

20.0 - 23.0 |

Max 1.0 |

8.0 - 10.0 |

3.15 - 4.15 |

Max 0.40 |

Max 0.40 |

Max 5.00 |

Re - mainder |

Specifications : ASTM B446, ASTM F3056

Size

0~15㎛, 15~45㎛, 15~53㎛, 45~106㎛, 45~150㎛, Etc. (Customized powder size for other Additive Manufacturing process)

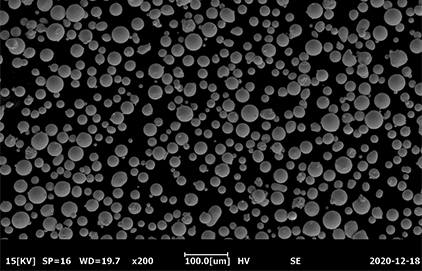

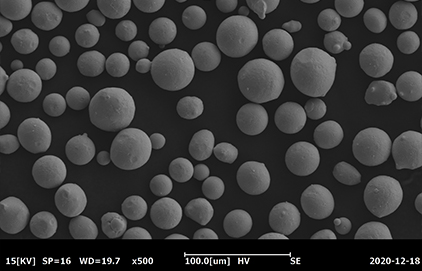

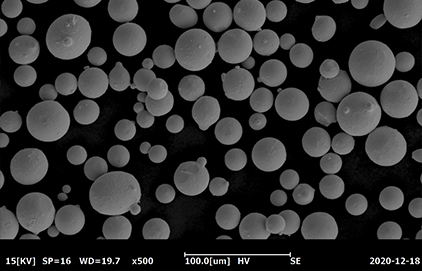

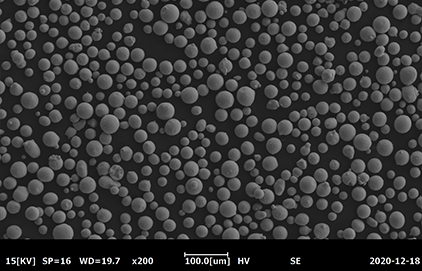

SEM image (ALY718 15~45㎛)

x200

x500

Application : Aerospace, Marine Industries

Package : 5.0KGS

316L

COMPOSI

TION GRADE |

Cr |

Ni |

Mo |

Mn |

S |

C |

P |

N |

Si |

Fe |

| 316L |

16.0 - 18.0 |

10.0 - 14.0 |

2.0 - 3.0 |

Max. 2.00 |

Max 0.03 |

Max. 0.03 |

Max. 0.045 |

- |

Max. 1.00 |

Bal. |

Specifications : ASTM A479, ASTM F3184

630 (17-4PH)

COMPOSI

TION GRADE |

C |

Cr |

Ni |

Mn |

Si |

P |

S |

Cu |

Nb+Ta |

Fe |

| 630 |

Max. 0.07 |

15.0 - 17.5 |

3.0 - 5.0 |

Max. 1.00 |

Max 1.00 |

Max. 0.040 |

Max. 0.03 |

3.0 - 5.0 |

0.15-0.45 |

Bal. |

Specifications : ASTM A564

Size

0~15㎛, 15~45㎛, 15~53㎛, 45~106㎛, 45~150㎛, Etc. (Customized powder size for other Additive Manufacturing process)

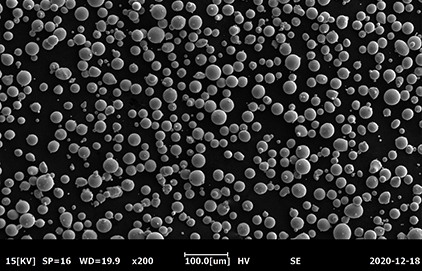

SEM image (316L 15~45㎛)

x200

x500

Application : Aerospace, Marine Industries

Package : 5.0KGS